The basic idea of the lean is to increase the customer value through continuous improvement and less resource while eliminating waste of time and effort and other non-value added activities. Lean is all about the smooth flow of process.

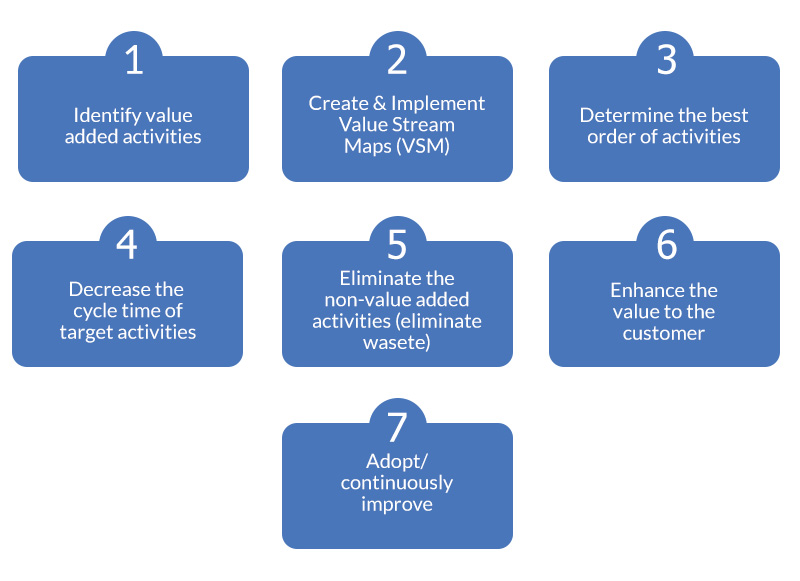

7 key steps to implement Lean principles

The current Global recession in the worldwide economies is creating acute pressure and everyone is focusing on reducing expenses and improving profitability. In these circumstances, the organizations that respond well, manifest quickly from today’s economic crisis. So it is lean that help companies in restructuring and cost-cutting. It decreases the cycle time increasing efficiency gains and enhances the value-added services to the customer. “The Value-adding activities are simply only those things the customer is willing to pay for, everything else is waste, and should be eliminated, simplified, reduced, or integrated” (Rizzardo, 2003).

Lean can be applied in any process or business. It is absolutely not only a cost reduction program but an entirely different conception and idea for organizational improvement. The basic concept behind lean is to improve systematically a messy home or workplace, troublesome and fatiguing to find things, rather it improves overall system by recognizing its all interfaces.

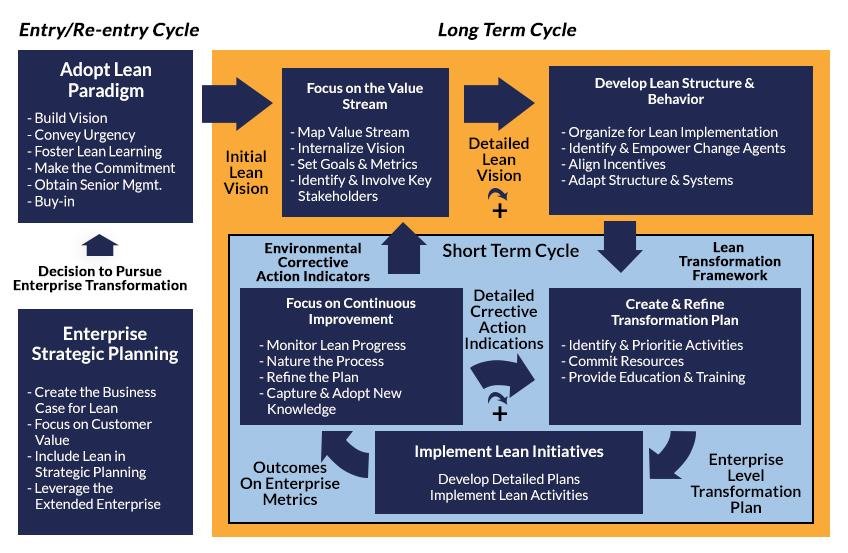

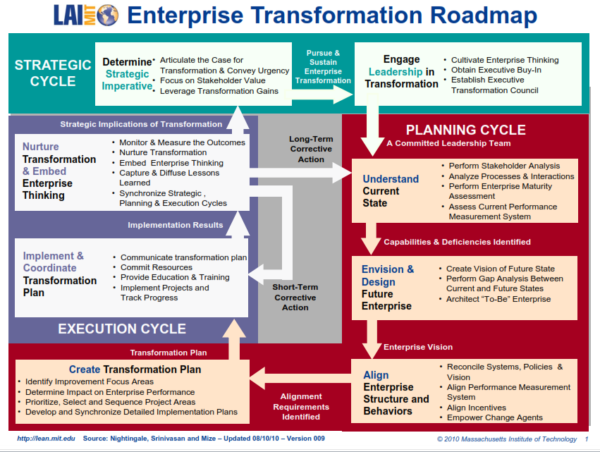

Our unique engagement model based on customer satisfaction and savings plan help them to define their roadmap and priorities, Please see our engagement model.

Usually, organizations have achieved 10-20% overall improvement in healthcare businesses by the successful implementation of Lean principles.

Lean can be applied in any process or business including manufacturing or processing industries. It helps to improve overall business performance.

7formations helps organizations through following key concepts to implement Lean Principles in manufacturing industries based on our past performances in some of leading manufacturing industries both in East & West Coast of United States;

- Value Stream Mapping (VSM) to figure out actual flow to map future state of organization for performance modeling

- Define all steps with respect to time of selected process including sales, purchases, engineering, shipping, plants’ processes and customer services related processes

- Process performance baselines and Models in focused areas of improvement

- Automated mechanism and procedures for data collection and management reviews

- Reports creation and integration of management systems including Quality, Environment, Energy systems and regulatory requirements

- Implement Just In Time (JIT) inventory concepts and establish Inventory System

- Defining and benchmarking Overall Equipment Effectiveness (OEE), Total Effective Equipment Performance (TEEP) as Key Performance indicator (KPI’s) in conjunction with lean manufacturing as performance indicators

- Automated OEE and TEEP calculations in Enterprise Asset Management through integration with existing ERP solutions or Plant Floor Networks.

7formations’ helps its clients to adopt quality systems with lean principles. Few examples of lean implementation;

-

- Avoiding over documentation of QMS

- Continuous improvement

- Agile principles implementation

- Avoid duplication of documents in Quality Manual

- Value stream mapping concept in documentation

- Change management system

- Avoid waste of time in lengthy approval process of documentation

- Reduce waste of money in over killing of process